Laps: 3D Warehouse Inventory Management

A revolutionary approach to warehouse management using 3D visualization and real-time tracking

Year

2022

Client

Twinzo 3D

Role

Frontend Developer (Flutter), UX/UI Designer

Project Overview

Laps is a SaaS-based warehouse inventory management system designed for Fortune 500 clients. The platform integrates 3D data visualization with real-time inventory tracking to provide an intuitive and comprehensive solution for managing complex warehouse operations. By transforming traditional inventory management into an interactive 3D experience, Laps enables warehouse managers to optimize space utilization, improve picking efficiency, and reduce operational costs.

The Challenge

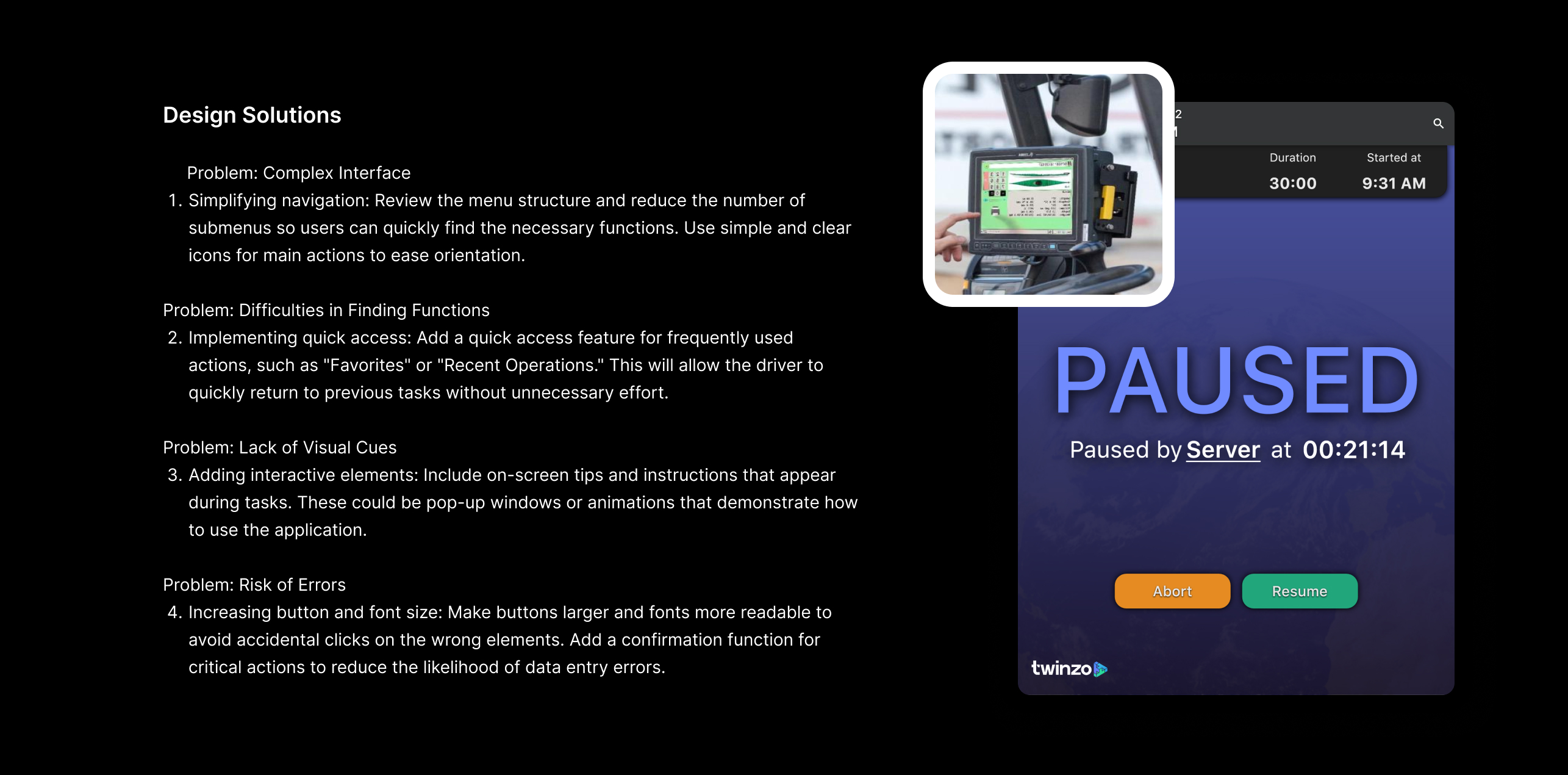

Large enterprises faced several critical challenges with traditional warehouse management:

- 1Difficulty visualizing complex warehouse layouts and inventory positions across multiple locations

- 2Inefficient picking routes leading to wasted time and increased labor costs

- 3Lack of real-time visibility into inventory movements and stock levels

- 4High training costs for new warehouse staff due to complex systems

The Solution

- Interactive 3D Visualization

Digital twin of the physical warehouse with real-time inventory representation

- Mobile Application

Cross-platform app for warehouse staff to track, locate, and manage inventory on the go

- Real-time Analytics

Comprehensive dashboards for monitoring KPIs and optimizing warehouse operations

- Optimized Picking Routes

AI-powered route optimization to minimize travel time and increase efficiency

App Values

Project Scope

Mobile Application

- • Cross-platform Flutter development

- • Real-time inventory tracking

- • Barcode/QR scanning

- • Task management

- • Offline functionality

- • Push notifications

Server Infrastructure

- • Cloud-based architecture

- • Real-time data synchronization

- • API development

- • Database optimization

- • Authentication & security

- • Analytics processing

Admin Dashboard

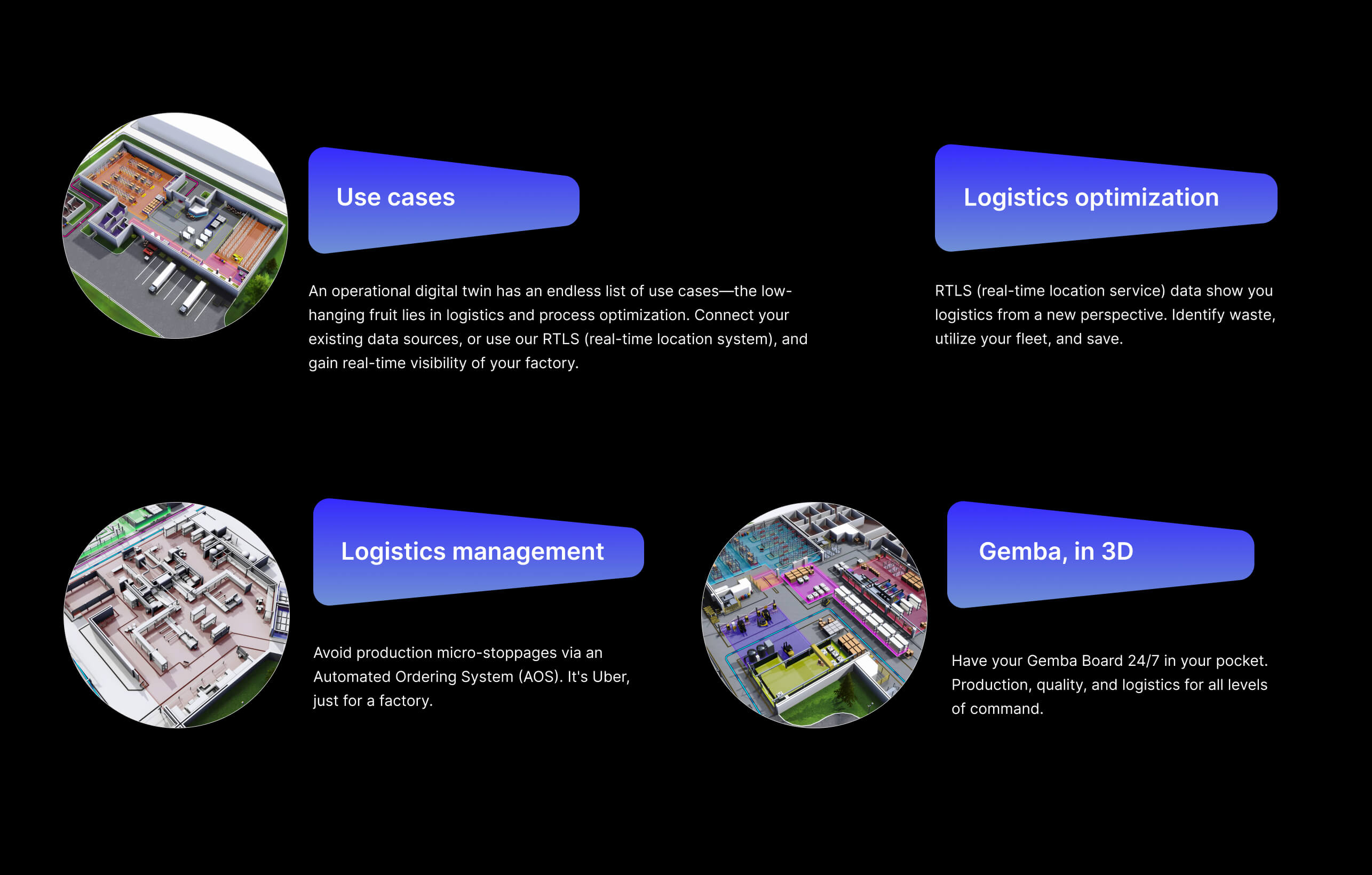

- • 3D warehouse visualization

- • Inventory management

- • Staff performance tracking

- • Reporting & analytics

- • System configuration

- • User management

Key Features

3D Warehouse Visualization

Interactive digital twin of the physical warehouse that allows managers to zoom, rotate, and explore the entire facility. The system shows real-time inventory positions, stock levels, and staff locations, making it easy to understand complex spatial relationships at a glance.

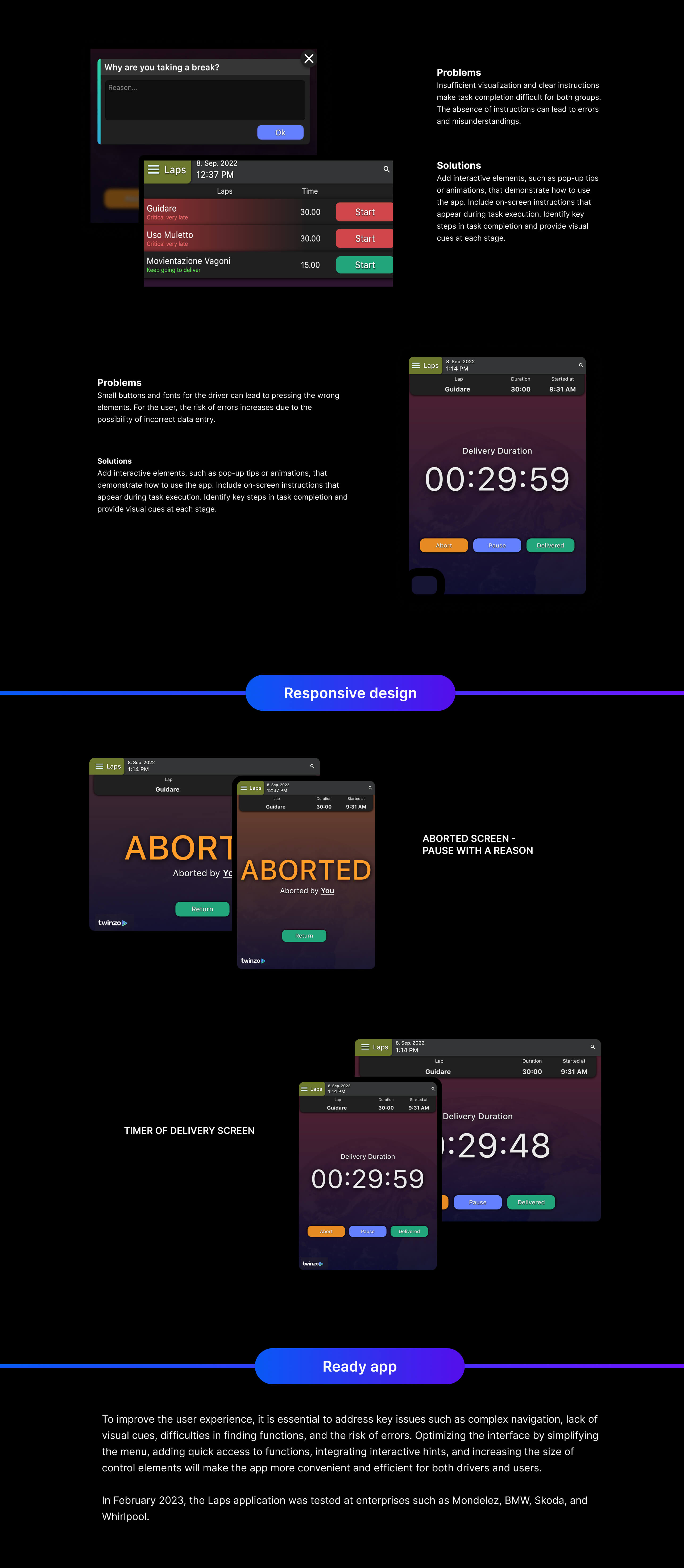

Time Tracking & Optimization

Sophisticated time tracking for all warehouse operations, from picking and packing to inventory counts. The system analyzes historical data to identify bottlenecks and suggest process improvements, helping to reduce operational costs and increase throughput.

Intelligent Inventory Management

Advanced inventory management with predictive analytics for stock optimization. The system automatically suggests optimal inventory levels based on historical data, seasonal trends, and current demand, helping to reduce carrying costs while preventing stockouts.

Real-time Analytics Dashboard

Comprehensive analytics dashboard providing insights into key performance indicators such as picking efficiency, inventory turnover, space utilization, and labor productivity. Custom reports can be generated and scheduled for regular distribution to stakeholders.

Mobile Application

Warehouse Staff Features

- Real-time task assignments with priority indicators

- Optimized picking routes with turn-by-turn navigation

- Barcode and QR code scanning for inventory verification

- Time tracking for task completion and performance metrics

Manager Features

- Staff performance monitoring and task assignment

- Inventory alerts and exception handling

- Mobile access to key performance indicators and reports

- Approval workflows for inventory adjustments and transfers

Technical Implementation

Technology Stack

Flutter

Mobile App

Unity 3D

Visualization

Node.js

Backend

MongoDB

Database

WebSockets

Real-time Updates

TensorFlow

Predictive Analytics

AWS

Cloud Infrastructure

Figma

Design

Development Approach

The project was developed using an agile methodology with two-week sprints. The development process was divided into three main phases:

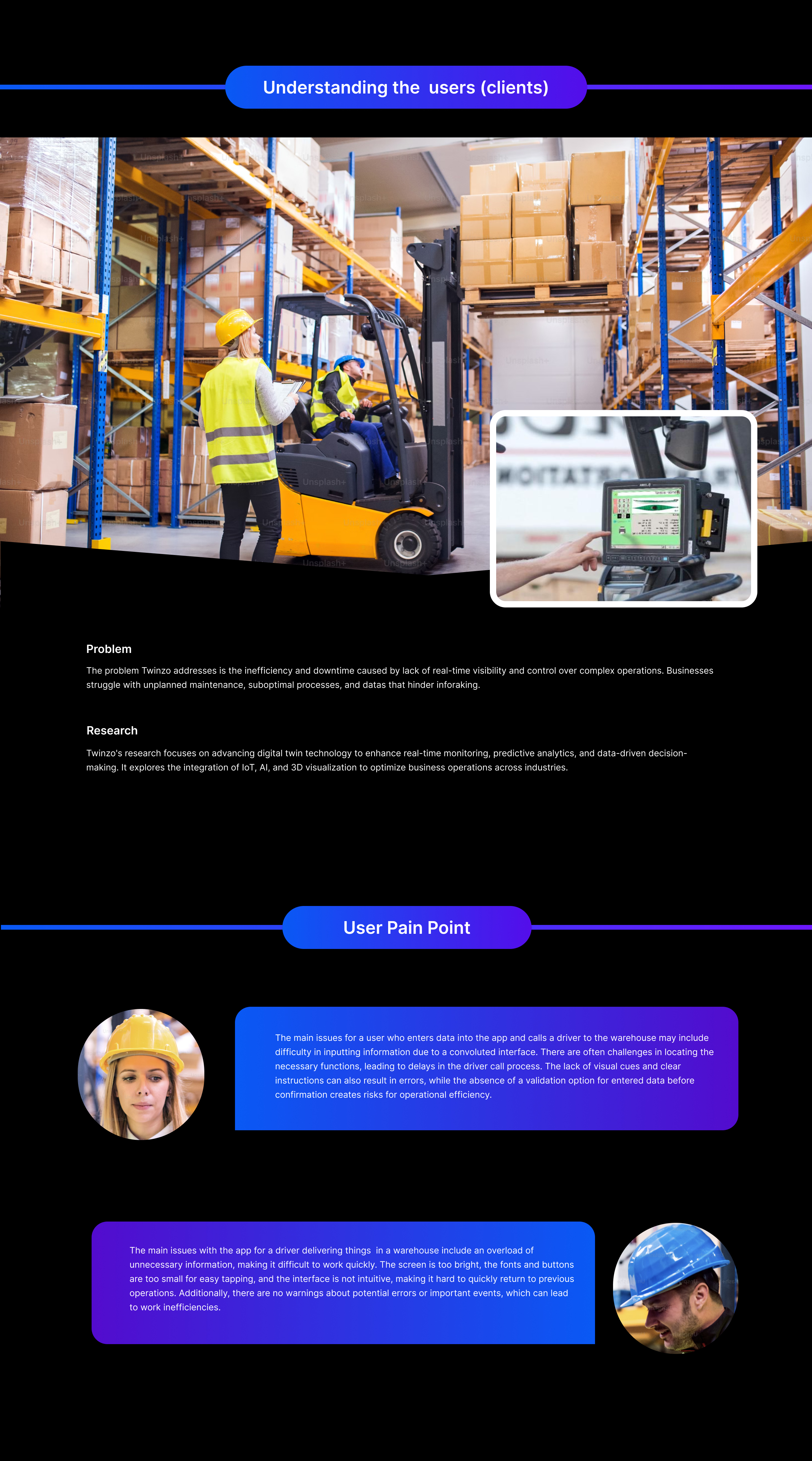

Discovery & Design

Managers conducted extensive user research with warehouse staff and managers to understand pain points and requirements. Created wireframes and interactive prototypes for user testing before finalizing the design.

Core Development

Twinzo builts the foundational components including the 3D visualization engine, mobile application, and backend infrastructure. Implemented core features and established data synchronization between components.

Refinement & Deployment

Teams conducted extensive testing in real warehouse environments, gathering feedback and making iterative improvements. Optimized performance and implemented advanced features before final deployment.

Results & Impact

Key Outcomes

- Enhanced usability and adoption rates among warehouse staff, resulting in more efficient inventory management

- Reduced training time for new employees by due to the intuitive 3D interface

- Improved inventory accuracy, leading to fewer stockouts and overstock situations

- Optimized warehouse space utilization through better placement strategies

- Increased picking efficiency, resulting in faster order fulfillment and reduced labor costs